Never wait for help. We're available 24/7.

Call Now: 781-782-2382

Never wait for help. We're available 24/7.

Call Now: 781-782-2382

In Massachusetts, keeping your commercial or industrial electrical panels safe isn’t just smart — it’s required. Whether you run a manufacturing plant in Everett, a warehouse in South Boston, or a large retail store in Dorchester, electrical panel safety and compliance are critical for protecting your people, your property, and your business operations.

At Castro Electric, we’ve seen how neglected panels can lead to costly violations, unexpected downtime, and even dangerous electrical hazards. This guide will walk you through our industrial panel safety & compliance checklist — tailored for Boston-area facilities — so you can stay OSHA-compliant and Massachusetts Electrical Code ready.

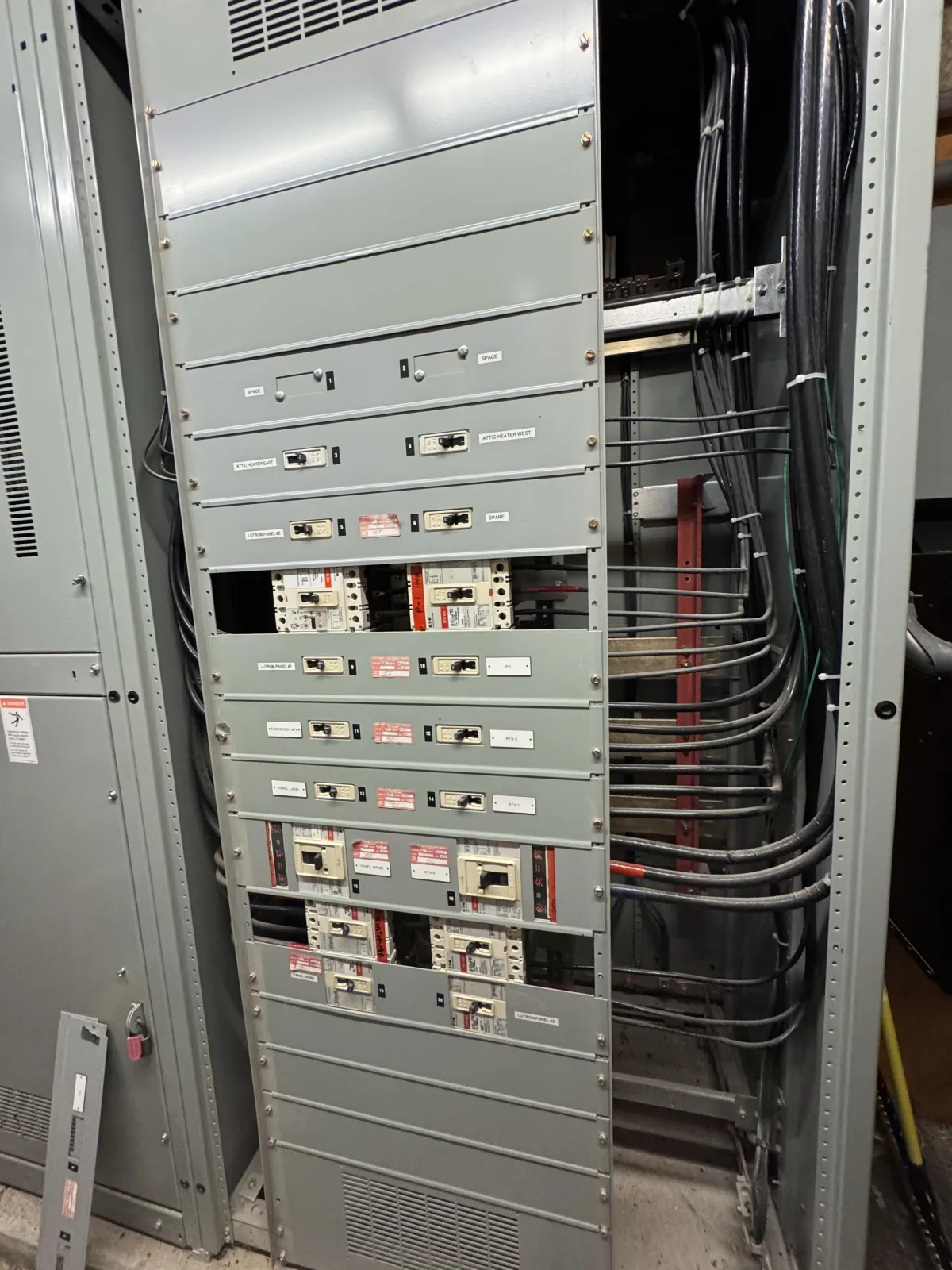

An electrical panel is the control center for your facility’s power distribution. In an industrial setting, a single malfunction can bring production to a halt or create a serious safety risk.

Safe, compliant panels:

Deliver consistent, reliable power to equipment

Minimize fire hazards and electrical accidents

Meet insurance and inspection requirements

Reduce the likelihood of costly downtime

Neglected panels, on the other hand, are a leading cause of workplace electrical fires and OSHA citations. According to the National Fire Protection Association, electrical distribution equipment was involved in an estimated 24% of industrial fires between 2015 and 2019.

Massachusetts adopts the National Electrical Code (NEC) with its own amendments. For commercial and industrial properties in Boston, inspections may be required during:

Facility construction or expansion

Equipment installation requiring new circuits

Safety audits or insurance renewals

Additionally, OSHA’s regulations for electrical safety in the workplace (29 CFR 1910 Subpart S) require panels to be accessible, labeled, and properly maintained.

Keep a minimum of 36 inches of clearance in front of each panel (OSHA standard 1910.303).

Avoid blocking access with boxes, carts, or equipment.

Each breaker should be accurately and legibly labeled with the equipment or area it serves.

Use durable labels resistant to heat, moisture, and wear.

All panel covers should be securely fastened.

Hinges and latches must operate smoothly, without rust or damage.

Look for scorch marks, discoloration, or melting.

Panels should not feel warm during normal operation — overheating can signal overload or loose connections.

Ensure the panel is correctly grounded and bonded according to NEC and Massachusetts amendments.

Grounding prevents dangerous voltage build-up and equipment damage.

Schedule yearly inspections with a licensed commercial electrician familiar with MA code.

Keep inspection records for insurance and compliance purposes.

Use lockout/tagout devices during maintenance.

Ensure your team is trained on LOTO procedures to prevent accidental energization.

Panels should have capacity for your current load and any planned expansions.

Overloaded panels can cause breaker trips, equipment failure, or fires.

Panels should be in clean, dry locations — excessive dust or moisture can accelerate corrosion and failures.

Keep all panel schematics, permits, and past inspection reports accessible.

From our work across Greater Boston, the most frequent violations we encounter include:

Missing or incorrect labels on breakers

Panels blocked by storage or equipment

Unsecured panel doors or missing covers

Overloaded panels serving equipment beyond capacity

Outdated panels that no longer meet NEC standards

These issues can result in failed inspections, OSHA citations, and increased insurance premiums.

A Boston-area food processing plant contacted us after failing an insurance inspection due to blocked panel access and outdated labeling. We reorganized their electrical room, updated all breaker labels, performed load balancing, and documented the work for their insurer. The plant passed its re-inspection without issue, and the improvements reduced breaker trips by 40%.

We go beyond a visual check — testing connections, verifying grounding, and evaluating load capacity.

If your panel is outdated, undersized, or unsafe, we recommend upgrades that meet NEC, OSHA, and Massachusetts standards.

We schedule inspections and repairs around your workflow to keep your operations running.

You get a complete report for your internal records, insurance, and compliance audits

Failing to maintain commercial electrical panel safety in MA can lead to:

OSHA fines ranging from hundreds to tens of thousands of dollars per violation

Insurance policy cancellations or premium increases

Equipment damage and production downtime

Increased fire risk and liability

A proactive inspection program is far less expensive than reacting to violations or emergencies.

Your electrical panel is the heartbeat of your industrial or commercial facility. Keeping it safe and compliant isn’t just about meeting regulations — it’s about protecting your people, equipment, and bottom line.

If you’re unsure about your facility’s compliance status, the safest next step is a professional inspection.

Schedule Your Industrial Panel Safety Inspection Today

Serving Boston, Stoneham, and Greater Boston Facilities

Call us at (781) 782-2382

Website by Up & Social